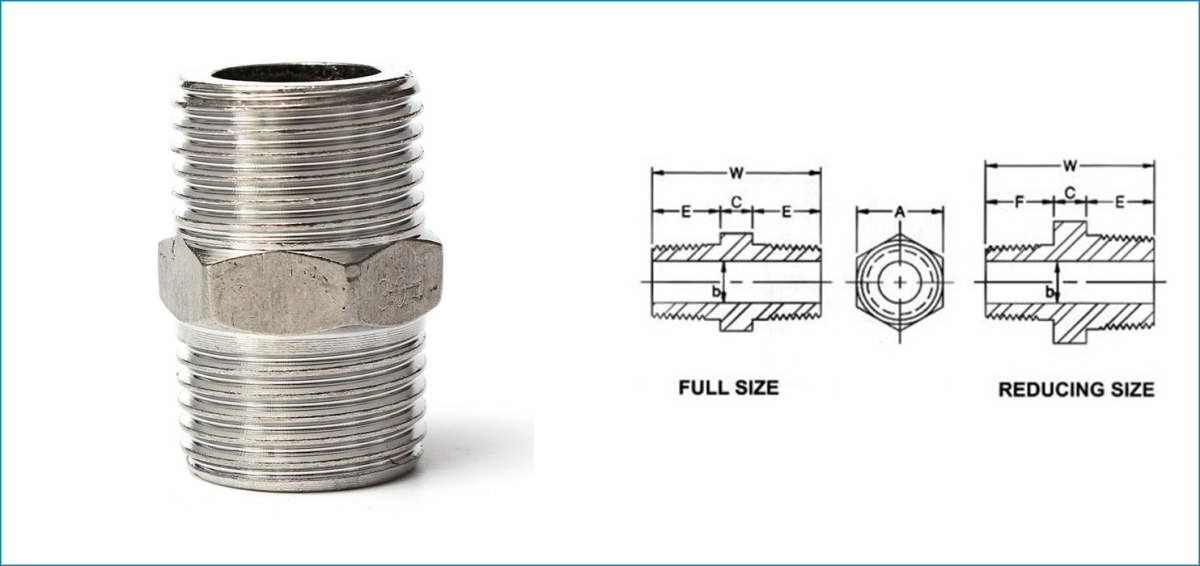

Post / Screwed Hex Nipple

An ISO certied turma, Liaocheng Shenghao metalla producta Co, LTD.princeps exportator, stockist ac elit Threaded / Screwed Hex Papillae.Summus qualitas materiae rudis adhibetur cum hodierno instrumento ad huiusmodi caerimonias producendas.Steel Threaded Hex papillae adhibentur ad ta rectae extremitatis fistulam vel caligarum.Probantur et verificantur ac comprobantur dimensionalem accurationem, diuturnitatem et praecisionem habere.Haec ANSI B16.11 Hex papillae in variis praesto suntfigurae, magnitudinum, crassitudinis et specificationum sicut per clientium requisita.Faciles sunt ad institutionem et corrosionem repugnant.Itawless consummationem et superiorem perficientur. Liaocheng Shenghao productorum Metallorum Co., LTD .invests in premium qualitas materiae rudis et modernae technologiae quae adiuvat ut ius genus productorum clientibus praebeat et sic maximam satisfactionem obtineat.Hae diaetae sub peritia professionalium creantur.

Post Hex Papilla Standard

| Dimensiones | ASME 16.11, MSS SP-79, MSS. SP-95, 83, 95, 97, BS |

| Magnitudo | 1/8″ NB TO 4″ NB |

| Classis | 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Threaded (S/W) & SCRWED (SCRD) - NPT, BSP, BSPT |

| Forma | Post Hex Nipple |

| Precium Added Services: | Hot Dipped Galvanizing, Epoxy & FBE Coating, Electro Polish, Sand Blasting, Threading, Soldering. |

| Gradus productio: | Stainless Steel, Alloy Steel, Duplex, Nickel Alloys, Low-temperate Steel, Carbon Steel, Cupro Nickel |

ASME B16.11 Threaded Hex Nipple Dimensiones Standrad

| SICUT ME: | ASME 16.11, MSS SP-79, MSS. SP-95, 83, 95, 97, BS |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

ASME B16.11 Threaded Hex Papilla Material

ASME B16.11 Steel Forged Threaded Hex Papilla:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F347, F347, F340 TP304, TP304L, TP316, TP316L

Duplex & Super Duplex Steel ASME B16.11

ASTM A 182 - F 51, F53, F55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Carbon Ferro ASME B16.11 Falsa Threaded Reducing Papilla:

ASTM/ ASME A 105, ASTM/ ASME A 350 LF 2, ASTM / ASME A 53 GR.A & B, ASTM A 106 GR.A, B & C. API 5L GR.B, API 5L X 42, X 46, X 52, X 60, X 65 & X 70. ASTM/ASME A 691 GR A, B & C

ASME B16.11 Admisce Ferro Forded Threaded Hex Papilla:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR , 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91

ASME B16.11 Aeris Alloy Steel Forged Threaded Reducing Papilla: ASTM / ASME SB 111 UNS NO.C 10100 , C 10200 , C 10300 , C 10800 , C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO.C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

Nickel Alloy Forded ASME B16.11 Reducing Papilla:

ASTM / ASME SB 336 , ASTM / ASME SB 564 / 160 / 163 / 472 , UNS 2200 ( NICKEL 200 ) , UNS 2201 ( NICKEL 201 ) , UNS 4400 ( MONEL 400 ) , UNS 8020 UNS INCONELIUS (825), UNS

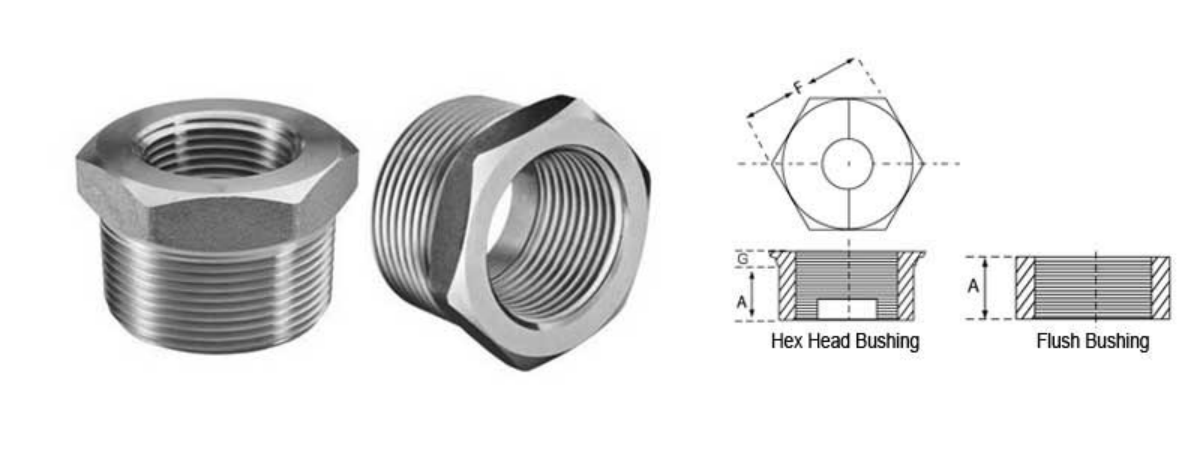

Post Reducing Papilla Dimensiones

ANSI/ASME B16.11 FILUM BUSHING DIMENSIONES

Post Reducing Bushing Dimensiones

| DIMENSIONES STATUM BUSHING (BS 3799) (In mm) | ||||

| Nominal | Longitudo | |||

| Hex Plugs & Bushings | ||||

| Latitudo blandit | Hex Height (Min.) | |||

| Bushing | Plug | |||

| 1/8" | 9.7 | 11.2 | - | 6.4 |

| 1/4" | 11.2 | 15.7 | 3.0 | 6.4 |

| 3/8" | 12.7 | 17.5 | 4.1 | 7.9 |

| 1/2" | 14.2 | 22.4 | 4.8 | 7.9 |

| 3/4" | 15.7 | 26.9 | 5.6 | 9.7 |

| 1" | 19.1 | 35.1 | 6.4 | 9.7 |

| 1-1/4" | 20.6 | 44.5 | 7.1 | 14.2 |

| 1-1/2" | 20.6 | 50.8 | 7.9 | 15.7 |

| 2" | 22.4 | 63.5 | 8.6 | 17.5 |

| 2-2/2" | 26.9 | 76.2 | 9.7 | 19.1 |

| 3" | 28.4 | 88.9 | 10.4 | 20.6 |

| 4" | 31.8 | 117.3 | 12.7 | 25.4 |

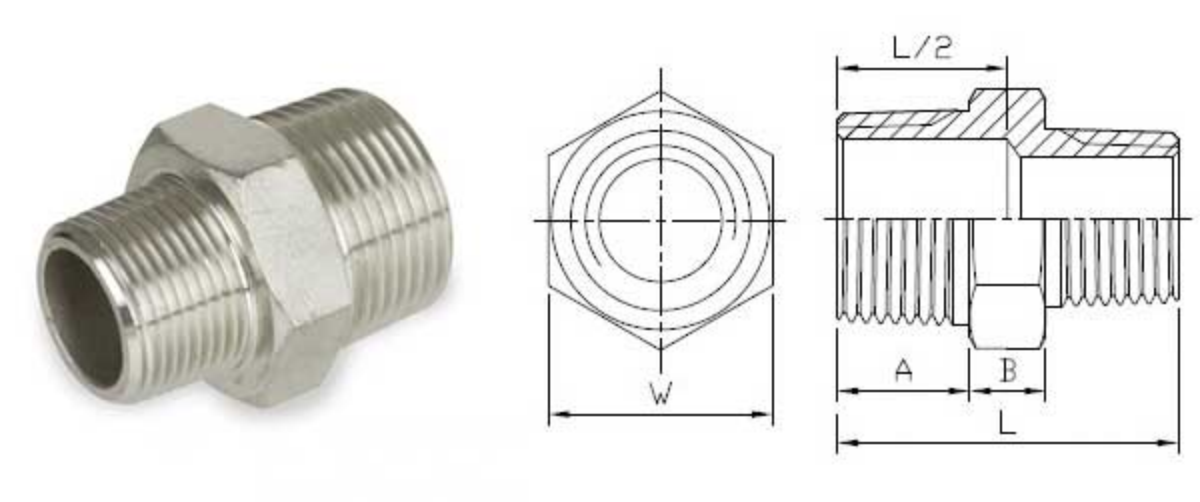

Post Hex caput Bushing Dimensiones

Standard PatternEconomic Pattern

| Standard Pattern | Exemplum oeconomicum | ||||||||||||||||||

| MENSURA | A | B | L | W | MENSURA | A | B | L | W | ||||||||||

| mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | mm | in | ||||

| 1/4″ | 1/8″ | 13 | 0.51 | 6 | 0.24 | 31 | 1.22 | 15.1 | 0.59 | 1/4″ | 1/8″ | 11 | 0.43 | 6 | 0.24 | 29 | 1.14 | 15 | 0.59 |

| 3/8″ | 1/8″ | 14 | 0.55 | 7 | 0.28 | 34 | 1.34 | 18.6 | 0.73 | 3/8″ | 1/8″ | 12 | 0.47 | 7 | 0.28 | 31 | 1.22 | 18 | 0.71 |

| 1/4″ | 14 | 0.55 | 7 | 0.28 | 34 | 1.34 | 18.6 | 0.73 | 1/4″ | 12 | 0.47 | 7 | 0.28 | 32 | 1.26 | 18 | 0.71 | ||

| 1/2″ | 1/8″ | 16.5 | 0.65 | 8 | 0.31 | 36.5 | 1.44 | 23 | 0.91 | 1/2″ | 1/8″ | 14 | 0.55 | 7 | 0.28 | 34 | 1.34 | 23 | 0.91 |

| 1/4″ | 16.5 | 0.65 | 8 | 0.31 | 36.5 | 1.44 | 23 | 0.91 | 1/4″ | 14 | 0.55 | 7 | 0.28 | 35 | 1.38 | 23 | 0.91 | ||

| 3/8″ | 16.5 | 0.65 | 8 | 0.31 | 36.5 | 1.44 | 23 | 0.91 | 3/8″ | 14 | 0.55 | 7 | 0.28 | 36 | 1.42 | 23 | 0.91 | ||

| 3/4″ | 1/8″ | 16 | 0.63 | 8 | 0.31 | 40 | 1.57 | 29 | 1.14 | 3/4″ | 1/8″ | 14 | 0.55 | 7 | 0.28 | 34 | 1.34 | 29 | 1.14 |

| 1/4″ | 16 | 0.63 | 8 | 0.31 | 40 | 1.57 | 29 | 1.14 | 1/4″ | 14 | 0.55 | 7 | 0.28 | 35 | 1.38 | 29 | 1.14 | ||

| 3/8″ | 17 | 0.67 | 8 | 0.31 | 41 | 1.61 | 28.5 | 1.12 | 3/8″ | 14 | 0.55 | 7 | 0.28 | 36 | 1.42 | 29 | 1.14 | ||

| 1/2″ | 17 | 0.67 | 8 | 0.31 | 41.5 | 1.63 | 28.5 | 1.12 | 1/2″ | 14 | 0.55 | 7 | 0.28 | 39 | 1.54 | 29 | 1.14 | ||

| 1″ | 1/4″ | 20 | 0.79 | 9 | 0.35 | 41 | 1.61 | 35.4 | 1.39 | 1″ | 1/4″ | 17.5 | 0.69 | 9 | 0.35 | 41 | 1.61 | 35 | 1.38 |

| 3/8″ | 20 | 0.79 | 9 | 0.35 | 42.5 | 1.67 | 35.4 | 1.39 | 3/8″ | 17.5 | 0.69 | 9 | 0.35 | 42 | 1.65 | 35 | 1.38 | ||

| 1/2″ | 20 | 0.79 | 9 | 0.35 | 45 | 1.77 | 35.4 | 1.39 | 1/2″ | 17.5 | 0.69 | 9 | 0.35 | 45 | 1.77 | 35 | 1.38 | ||

| 3/4″ | 20 | 0.79 | 9 | 0.35 | 45 | 1.77 | 35.4 | 1.39 | 3/4″ | 17.5 | 0.69 | 9 | 0.35 | 45 | 1.77 | 35 | 1.38 | ||

| 1-1/4″ | 1/4″ | 21 | 0.83 | 10 | 0.39 | 42 | 1.65 | 44.5 | 1.75 | 1-1/4″ | 1/4″ | 18 | 0.71 | 10 | 0.39 | 42 | 1.65 | 45 | 1.77 |

| 3/8″ | 21 | 0.83 | 10 | 0.39 | 47 | 1.85 | 44.5 | 1.75 | 3/8″ | 18 | 0.71 | 10 | 0.39 | 43 | 1.69 | 45 | 1.77 | ||

| 1/2″ | 21 | 0.83 | 10 | 0.39 | 49 | 1.93 | 44.5 | 1.75 | 1/2″ | 18 | 0.71 | 10 | 0.39 | 46 | 1.81 | 45 | 1.77 | ||

| 3/4″ | 21 | 0.83 | 10 | 0.39 | 49 | 1.93 | 44.5 | 1.75 | 3/4″ | 18 | 0.71 | 10 | 0.39 | 46 | 1.81 | 45 | 1.77 | ||

| 1″ | 22 | 0.87 | 10 | 0.39 | 52 | 2.05 | 44.5 | 1.75 | 1″ | 18 | 0.71 | 10 | 0.39 | 50 | 1.97 | 45 | 1.77 | ||

| 1-1/2″ | 1/4″ | 20 | 0.79 | 10.5 | 0.41 | 42.5 | 1.65 | 51 | 2.01 | 1-1/2″ | 1/4″ | 18.5 | 0.73 | 10.5 | 0.41 | 42.5 | 1.67 | 50 | 1.97 |

| 3/8″ | 21 | 0.83 | 10 | 0.39 | 47 | 1.85 | 50 | 1.97 | 3/8″ | 18.5 | 0.73 | 10.5 | 0.41 | 43.5 | 1.71 | 50 | 1.97 | ||

| 1/2″ | 21 | 0.83 | 10 | 0.39 | 49 | 1.93 | 50 | 1.97 | 1/2″ | 18.5 | 0.73 | 10.5 | 0.41 | 46.5 | 1.83 | 50 | 1.97 | ||

| 3/4″ | 21 | 0.83 | 10 | 0.39 | 49 | 1.93 | 50 | 1.97 | 3/4″ | 18.5 | 0.73 | 10.5 | 0.41 | 46.5 | 1.83 | 50 | 1.97 | ||

| 1″ | 21.5 | 0.85 | 11 | 0.39 | 52.5 | 2.07 | 50 | 1.97 | 1″ | 18.5 | 0.73 | 10.5 | 0.41 | 50.5 | 1.99 | 50 | 1.97 | ||

| 1-1/4″ | 22 | 0.87 | 11 | 0.43 | 55 | 2.17 | 51 | 2.01 | 1-1/4″ | 18.5 | 0.73 | 10.5 | 0.41 | 50.5 | 1.99 | 50 | 1.97 | ||

| 2″ | 3/8″ | 23 | 0.91 | 11 | 0.43 | 52 | 2.05 | 61.5 | 2.42 | 2″ | 3/8″ | 20 | 0.79 | 11 | 0.43 | 45 | 1.77 | 62 | 2.44 |

| 1/2″ | 23 | 0.91 | 11 | 0.43 | 52 | 2.05 | 61.5 | 2.42 | 1/2″ | 20 | 0.79 | 11 | 0.43 | 48 | 1.89 | 62 | 2.44 | ||

| 3/4″ | 23 | 0.91 | 11 | 0.43 | 41.5 | 1.63 | 61.5 | 2.42 | 3/4″ | 20 | 0.79 | 11 | 0.43 | 48 | 1.89 | 62 | 2.44 | ||

| 1″ | 23 | 0.91 | 11 | 0.43 | 53.5 | 2.11 | 61.5 | 2.42 | 1″ | 20 | 0.79 | 11 | 0.43 | 52 | 2.05 | 62 | 2.44 | ||

| 1-1/4″ | 23 | 0.91 | 11 | 0.43 | 56 | 2.2 | 61.5 | 2.42 | 1-1/4″ | 20 | 0.79 | 11 | 0.43 | 52 | 2.05 | 62 | 2.44 | ||

| 1-1/2″ | 23 | 0.91 | 11 | 0.43 | 55.5 | 2.19 | 61.5 | 2.42 | 1-1/2″ | 20 | 0.79 | 11 | 0.43 | 52 | 2.05 | 62 | 2.44 | ||

| 2-1/2″ | 3/4″ | 27.5 | 1.08 | 13 | 0.51 | 64 | 2.52 | 78 | 3.07 | 2-1/2″ | 3/4″ | 22.5 | 0.89 | 13 | 0.51 | 52.5 | 2.07 | 78 | 3.07 |

| 1″ | 27.5 | 1.08 | 13 | 0.51 | 63.5 | 2.5 | 78 | 3.07 | 1″ | 22.5 | 0.89 | 13 | 0.51 | 56.5 | 2.22 | 78 | 3.07 | ||

| 1-1/4″ | 27.5 | 1.08 | 13 | 0.51 | 63.5 | 2.5 | 78 | 3.07 | 1-1/4″ | 22.5 | 0.89 | 13 | 0.51 | 56.5 | 2.22 | 78 | 3.07 | ||

| 1-1/2″ | 27.5 | 1.08 | 13 | 0.51 | 63.5 | 2.5 | 78 | 3.07 | 1-1/2″ | 22.5 | 0.89 | 13 | 0.51 | 56.5 | 2.22 | 78 | 3.07 | ||

| 2″ | 27.5 | 1.08 | 13 | 0.51 | 65.5 | 2.58 | 78 | 3.07 | 2″ | 22.5 | 0.89 | 13 | 0.51 | 57.5 | 2.26 | 78 | 3.07 | ||

| 3″ | 1-1/2″ | 28 | 1.1 | 15 | 0.59 | 68 | 2.68 | 92 | 3.62 | 3″ | 1-1/2″ | 25 | 0.98 | 15 | 0.59 | 61 | 2.4 | 91 | 3.58 |

| 2″ | 28 | 1.1 | 15 | 0.59 | 68.5 | 2.7 | 93 | 3.66 | 2″ | 25 | 0.98 | 15 | 0.59 | 62 | 2.44 | 91 | 3.58 | ||

| 2-1/2″ | 28.5 | 1.12 | 15 | 0.59 | 71 | 2.8 | 92 | 3.62 | 2-1/2″ | 25 | 0.98 | 15 | 0.59 | 64.5 | 2.54 | 91 | 3.58 | ||

| 4″ | 2″ | 30 | 1.18 | 15 | 0.59 | 75 | 2.95 | 117 | 4.61 | 4″ | 2″ | 27 | 1.06 | 15 | 0.59 | 64 | 2.52 | 117 | 4.61 |

| 2-1/2″ | 30 | 1.18 | 15 | 0.59 | 75 | 2.95 | 117 | 4.61 | 2-1/2″ | 27 | 1.06 | 15 | 0.59 | 66.5 | 2.62 | 117 | 4.61 | ||

| 3″ | 30 | 1.18 | 15 | 0.59 | 75 | 2.95 | 117 | 4.61 | 3″ | 27 | 1.06 | 15 | 0.59 | 69 | 2.72 | 117 | 4.61 | ||

| Tolerantia: +0.5mm(1/8″~2″) | Tolerantia: +0.5mm(1/8″~2″) | ||||||||||||||||||

| +0.8mm(2-1/2″~4″) | |||||||||||||||||||