Unio Soldaturae Socketorum

Liaocheng Shenghao Metal products Co., LTD., ut exportator, distributor et venditor praecipuus iuncturarum iuncturarum ad suduram socketorum, constanter operam dedit ut amplam varietatem productorum clientibus suis praebeat. Societas est, quae certificatione ISO probata clientibus suis promittit ut summae qualitatis satisfaciant.producta. Uniones sudatae ex chalybe inoxidabili in tubis pressionis humilis adhibentur ubi tubum saepe disiungendum est. Unio sudata cum alveolis fabricata est consilium iuncturae cochleatae. Constat ex tribus partibus inter se conexis. Haec iunctura duos filos internos et partem mediam habet quae fines simul trahit cum rotatur. Ut...Ad deformationem sedilium minuendam, iunctiones arcte cochleandae sunt antequam extremitates suantur. ANSI B16.11 Unio Suturae SocketalisInstrumenta ad mensuras adaptabiles secundum petitiones emptorum praesto sunt. HGFF Group Co., Ltd. Socket sine ullo errore producit.Uniones Weld ut summam commoditatem clientibus suis praebeat.

Specificatio Normae Unionis Coniunctionis Socket Weld ANSI/ASME B16.11

| Dimensiones | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| Magnitudo | 1/8″ NB AD 4″ NB |

| Aestimationes Pressionis | Duae milia librarum, tria milia librarum, sex milia librarum, nonaginta milia librarum |

| Forma | Unio Sudurae Alveolaris, Unio Tubi Sudurae Alveolaris, Unio Orificii Sudurae Alveolaris, Unio Fucata, Compingmenta Unionis Sudurae Alveolaris |

| Gradus Productionis | Chalybs Inoxidabilis, Chalybs Mixtus, Duplex, Mixtiones Nickeli, Chalybs Temperaturae Humilis, Chalybs Carbonis, Cupro Nickel |

Normae Fabricationis Fibularum Unionerum Soldarum Socketorum

| ASME: | ASME 16.11, MSS SP-79, MSS SP-95, 83, 95, 97, BS 3799 |

| DIN: | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN: | EN10253-1, EN10253-2 |

Gradus Materialium Unionis Soldaturae Socketorum Fabricatae

Unio suturae socketorum fabricatae ex mixtura niccoli:

ASTM / ASME SB 336, ASTM / ASME SB 564 / 160 / 163 / 472, UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ANY 20/20 CB 3), UNS 8825 INCONEL UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276)

Unio suturae socketorum fabricatae chalybis inoxidabilis:

ASTM A182 F304, F304L, F306, F316L, F304H, F309S, F309H, F310S, F310H, F316TI, F316H, F316LN, F317, F317L, F321, F321H, F11, F22, F91, F347, F347H, F454L. ASTM A312/A403 TP304, TP304L, TP316, TP316L (vel: ASTM A312/A403 TP304, TP304L, TP316, TP316L)

Unio suturae involucri fabricatae chalybis duplex et superduplex:

ASTM A 182 – F 51, F 53, F 55 S 31803, S 32205, S 32550, S 32750, S 32760, S 32950.

Unio suturae socketorum fabricatae chalybis carbonis:

ASTM/ASME A 105, ASTM/ASME A 350 LF 2, ASTM/ASME A 53 Gradus A et B, ASTM A 106 Gradus A, B et C. API 5L Gradus B, API 5L X 42, X 46, X 52, X 60, X 65 et X 70. ASTM/ASME A 691 Gradus A, B et C.

Unio suturae socketorum fabricatae ex chalybe mixto:

ASTM / ASME A 182, ASTM / ASME A 335, ASTM / ASME A 234 GR P 1, P 5, P 9, P 11, P 12, P 22, P 23, P 91, ASTM / ASME A 691 GR 1 CR, 1 1/4 CR, 2 1/4 CR, 5 CR, 9CR, 91.

Coniunctio Suturæ Alveolaris Fabricatæ ex Chalybe Cupreo Mixto: ASTM / ASME SB 111 UNS NO. C 10100, C 10200, C 10300, C 10800, C 12000, C 12200, C 70600 C 71500, ASTM / ASME SB 466 UNS NO. C 70600 (CU-NI- 45/10), C 71500 (CU-NI- 70/30)

DIMENSIONES UNIONIS SODALIS ANSI/ASME B16.11

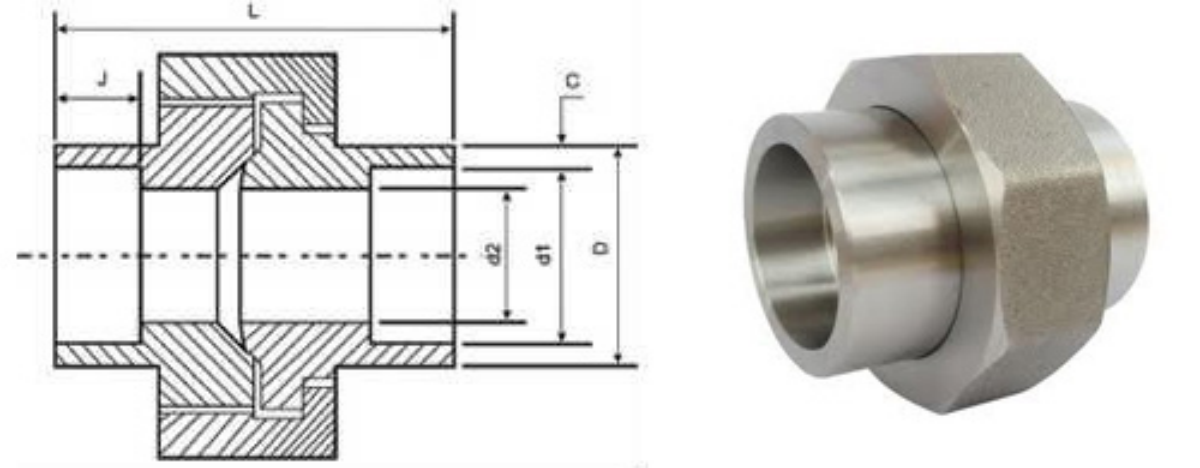

Dimensiones Unionis Tubi Soldati Socketorum

| Diameter Nominalis | Diameter Externus | Crassitudo muri | Foramen Socketi | Via aquatica foramen | Profunditas Alveoli | Longitudo Assem | |||

| Dmin | Cmin | d1 | d2 | Jmin | L | ||||

| DN | NPS | Socket | Filum | Socket | Filum | Socket | Socket & Threaded | Socket | Socket & Threaded |

| 6 | 1/8 | 21.8 | 14.7 | 3.2 | 2.5 | 10.65 | 6.43 | 10 | 41.4 |

| 8 | Quarta pars | 21.8 | 19.0 | 3.3 | 3.1 | 14.10 | 9.45 | 10 | 41.4 |

| 10 | 3/8 | 25.9 | 22.9 | 3.5 | 3.2 | 17.55 | 13.51 | 10 | 46.0 |

| 15 | Dimidium | 31.2 | 27.7 | 4.1 | 3.8 | 21.70 | 17.07 | 10 | 49.0 |

| 20 | Tres quartae partes | 37.1 | 33.5 | 4.3 | 4.0 | 27.05 | 21.39 | 13 | 56.9 |

| 25 | 1 | 45.5 | 41.4 | 5.0 | 4.6 | 33.80 | 27.74 | 13 | 62.0 |

| 32 | Quarta et undecima | 54.9 | 50.5 | 5.3 | 4.9 | 42.55 | 35.36 | 13 | 71.1 |

| 40 | 11/2 | 61.5 | 57.2 | 5.6 | 5.1 | 48.65 | 41.20 | 13 | 76.5 |

| 50 | 2 | 75.2 | 70.1 | 6.1 | 5.6 | 61.10 | 52.12 | 16 | 86.1 |

| 65 | XXI/II | 91.7 | 85.3 | 7.7 | 7.1 | 73.80 | 64.31 | 16 | 102.4 |

| 80 | 3 | 109.2 | 102.4 | 8.4 | 7.7 | 89.80 | 77.27 | 16 | 109.0 |

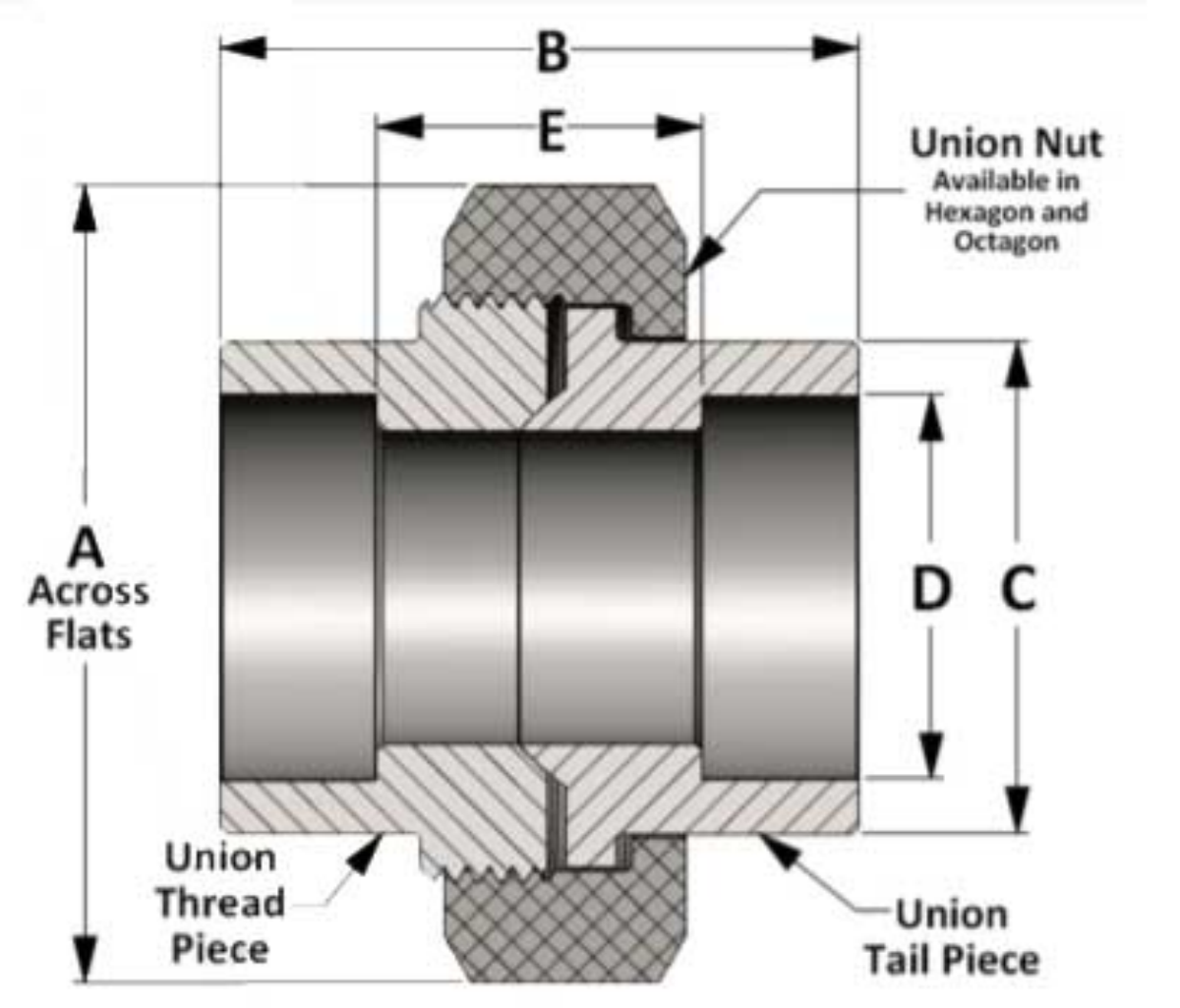

Unio Sudurae Socket Weight2 Unio Sudurae Socket

| Unio Soldabilis Socketorum CLASSIS 3000 | ||||||||||||

| MAGNITUDO TUBI | 1/8 | Quarta pars | 3/8 | Dimidium | Tres quartae partes | 1 | 1-1/4 | 1-1/2 | 2 | Duo et dimidium | 3 | 4 |

| A | 1.375 | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 |

| B | 1.688 | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | tria milia | 3.375 | 4.031 | 4.313 | Octo milia |

| C | 0.865 | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | 4.545 |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 2.313 | Quinque milia |

| LBS | 0.40 | 0.38 | 0.52 | 0.73 | 1.19 | 1.66 | 2.66 | 3.42 | 5.36 | 9.12 | 12.58 | 17.50 |

| Unio Soldabilis Socket Weld Classis 6000 | ||||||||||||

| MAGNITUDO TUBI | 1/8 | Quarta pars | 3/8 | Dimidium | Tres quartae partes | 1 | 1-1/4 | 1-1/2 | 2 | Duo et dimidium | 3 | 4 |

| A | 1.375 | 1.625 | 1.813 | 2.250 | 2.562 | 3.063 | 3.438 | 4.063 | 4.875 | 5.688 | 6.875 | — |

| B | 1.688 | 1.813 | 1.938 | 2.250 | 2.438 | 2.813 | tria milia | 3.375 | 4.031 | 4.313 | Octo milia | — |

| C | 0.865 | 1.025 | 1.235 | 1.465 | 1.795 | 2.165 | 2.425 | 2.965 | 3.615 | 4.305 | 5.415 | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | 3.536 | — |

| E | 0.813 | 0.813 | 0.938 | 0.938 | 1.125 | 1.188 | 1.438 | 1.500 | 1.625 | 2.250 | 5.750 | — |

| LBS | 0.48 | 0.56 | 0.75 | 1.35 | 2.01 | 3.17 | 3.92 | 6.60 | 10.12 | hora quarta decima | 40.891 | — |

| Unio Soldabilis Socket Weld Classis 9000 | ||||||||||||

| MAGNITUDO TUBI | 1/8 | Quarta pars | 3/8 | Dimidium | Tres quartae partes | 1 | 1-1/4 | 1-1/2 | 2 | Duo et dimidium | 3 | 4 |

| A | 1.750 | Duo milia | 2.250 | 2.563 | 3.063 | 3.688 | 4.313 | Quinque milia | 5.750 | 6.875 | — | — |

| B | 2.500 | 2.563 | 2.938 | 3.250 | 3.750 | quattuor milia | 4.625 | 4.813 | 5.563 | 6.25 | — | — |

| C | mille | 1.250 | 1.500 | 1.750 | 2.250 | 2.500 | tria milia | 3.625 | 4.250 | Quinque milia | — | — |

| D | 0.426 | 0.560 | 0.693 | 0.859 | 1.071 | 1.335 | 1.682 | 1.922 | 2.410 | 2.910 | — | — |

| E | 1.720 | 1.688 | 1.938 | Duo milia | 2.375 | 2.375 | tria milia | 2.938 | 3.188 | 3.750 | — | — |

| LBS | 0.89 | 1.045 | 1.955 | 3.29 | 5.34 | 7.99 | 12.73 | 18.34 | 26.36 | 37.07 | — | |

Applicatio Operculi Tubi Soldati Socketi Fabricati

Opercula tubi ASME B16.11 conglutinata nota sunt ob praeclaram efficaciam et plerumque elaborantur.

Ad necessitates implendas. Amplam seriem operculorum tuborum sudurae involucrorum fabricatorum per retem toto orbe terrarum offerimus.

ramorum qui merces custodiunt. Hoc operculum tubi fabricatum cum sutura involucri in variis adhibetur.industriae sicut:

Operculum tubi inoxidabilis e chalybe fabricato, conglutinatum, ad usum in tubis olei et gasi adhibetur.

Usus operculi tubi conglutinati fabricati in industria chemica

Usus operculi tubi ex chalybe mixto et alveolo conglutinati in plumbing

Usus operculorum tuborum extremitatum sudurae socketorum fabricatorum in calefactione

Usus operculorum tuborum fabricatorum sudurae socketorum in systematibus aquae suppeditandae

ANSI B16.11 Operculum tubi conglutinatum fabricatum in statione electrica adhibetur.

Usus operculi tubi conglutinati in industria chartae et pulpae

Usus operculorum tuborum fabricatorum cum alveolis sudurae in applicationibus generalibus

Usus operculi tubi fabricati cum sutura socketorum in industria fabricationis

Usus operculi tubi conglutinati fabricati in industria cibaria

Usus operculorum tuborum fabricatorum cum alveolis sudurae in tubis structuralibus